TECHNOLOGY

Research & Development

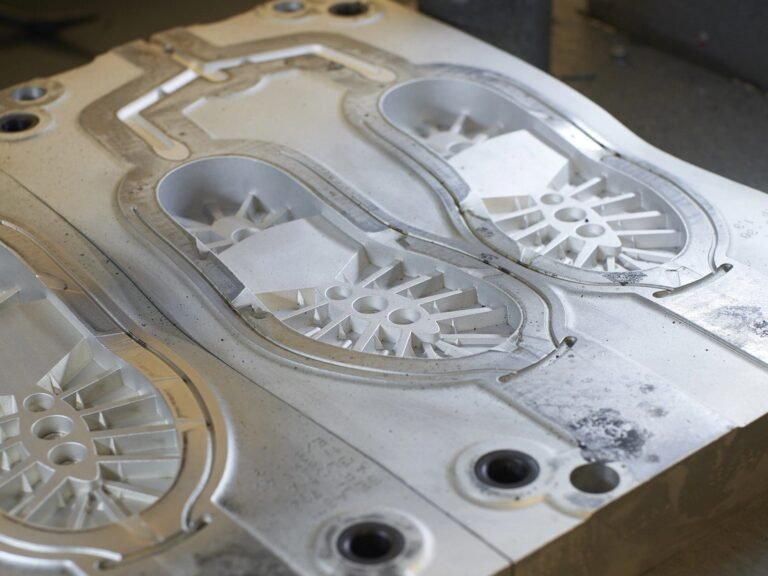

Rubber sole molds are precision-engineered tools—made through CAD/CAM, CNC machining, and casting—using iron or aluminum.

At our facility, we specialize in high-volume, precision manufacturing of rubber soles for a wide range of footwear—including athletic, safety, casual, formal and industrial applications.

Our infrastructure is designed to support both mass production and custom development projects with agility and consistency.

In-house mold production supports latest sole designs simultaneously, enabling fast model changes and seasonal updates

Quality Control

At our facility, quality is embedded at every stage of EVA sole production. Our dedicated Quality Control (QC) department ensures that every sole meets exacting standards for comfort, durability, safety, and aesthetic finish—matching both domestic and international requirements.

Mold Design & Engineering All EVA sole molds are designed in-house using the latest CAD software to simulate flow, filling, and release—ensuring accurate sole geometry, pattern detail, and logo placement. Our high-precision CNC machines translate designs into durable aluminum or iron molds with tight tolerances and high repeatability.

Mold Quality Control Procedures

Each mold cavity is checked using digital micrometers, calipers, and profile gauges to ensure accuracy to design specs.